Simulation to Optimize Production Planning

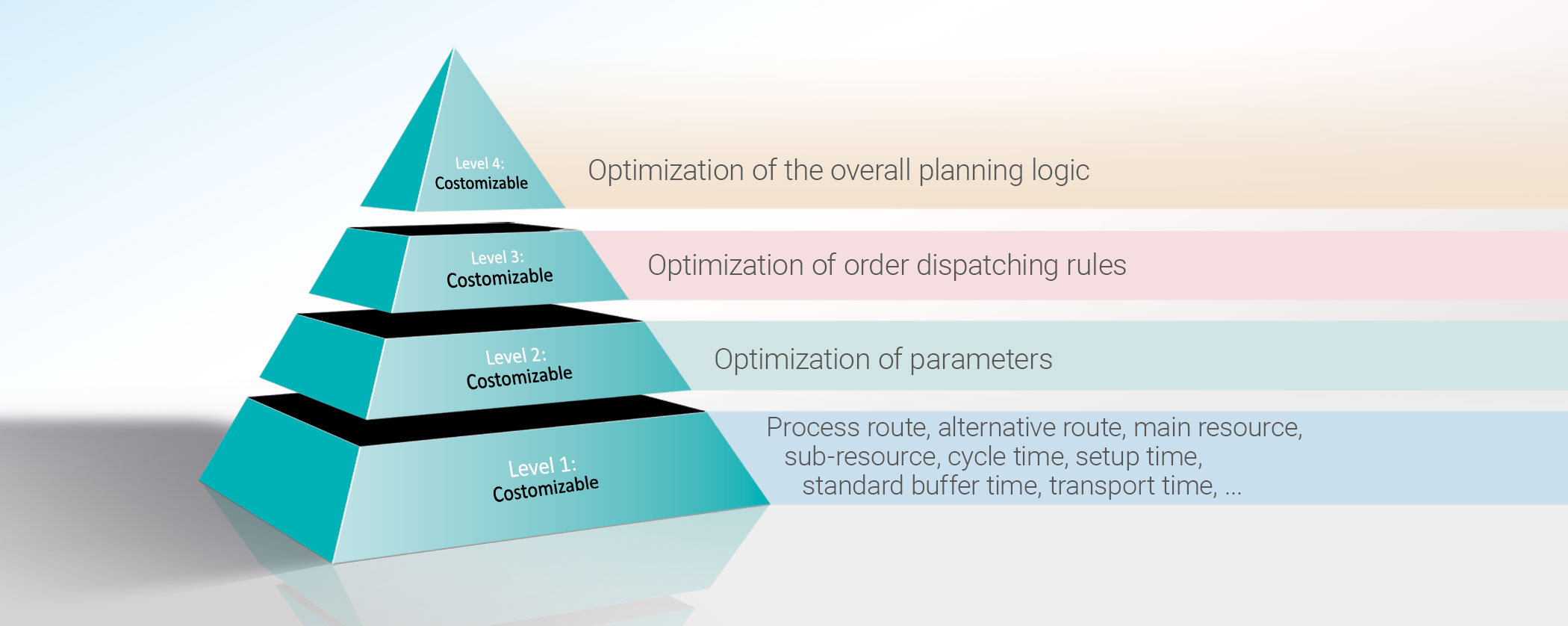

Optimization that is Based on Simulation

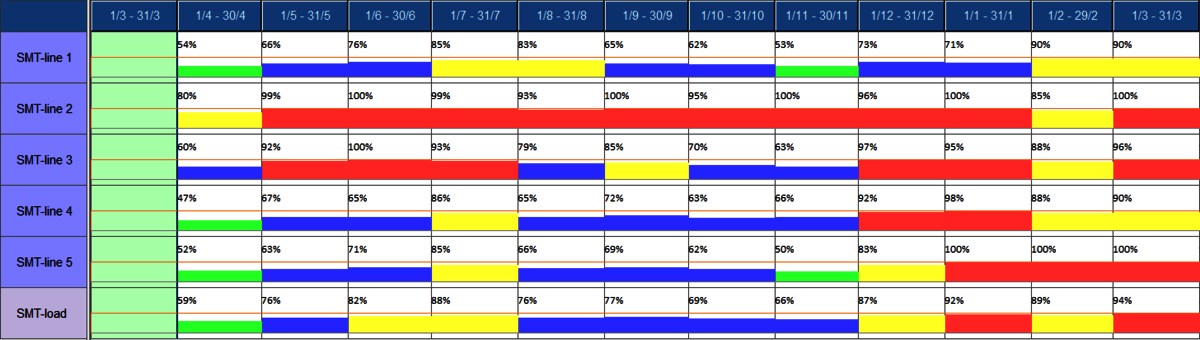

- Through simulations, optimal short-term, mid-term, and long-term production plans are brought forth. Cost, lead time, inventory and many more factors are taken into account.

- Potential bottlenecks can be identified up to months in advance, on the basis of which alternative scenarios help alleviate further problems – up to the point where production runs optimally.

- A variety of KPIs are provided with every scheduling run, aiding in selecting the best planning scenario.

- The feasibility of, especially, long-term business plans can be assessed accurately. For example, Asprova will indicate where necessary capacity adjustments need to be made.

Whitebox Instead of Blackbox: The APS System with Total Transparency

Changes made in one place can have effects in many other places. As the title imply, the mechanisms and workings behind tables, charts, and graphs can be tracked and studied, so that you gain a complete and in-depth understanding of Asprova APS and Asprova SCP.

Armed with knowledge of the logical consistency between settings and scheduling results, there are no limits on how you use Asprova to positively manipulate your production process and supply chain!

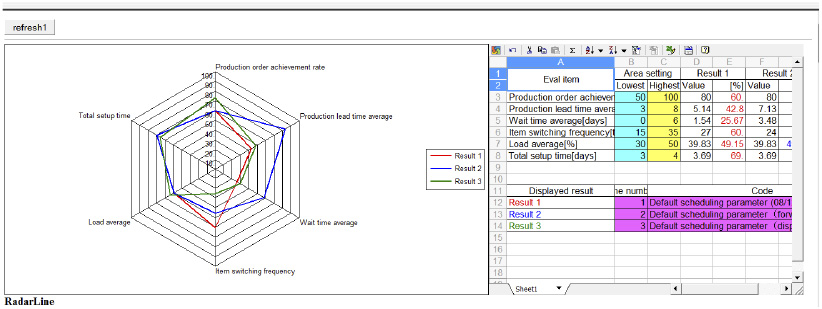

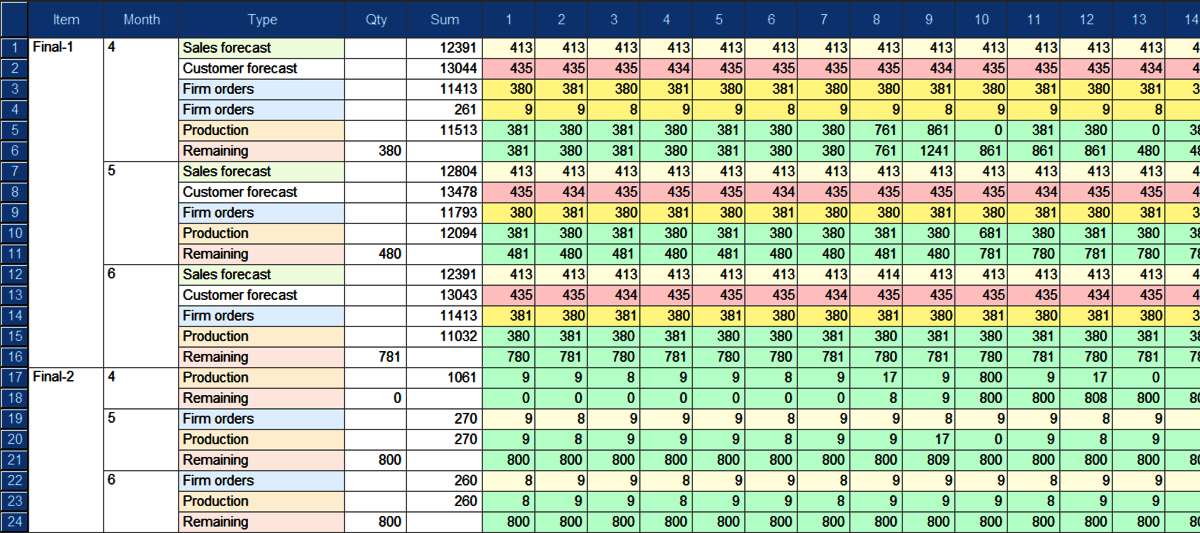

KPI — Key Performance IndicatorsMonitoring and Evaluating the Schedule Based on KPI.

- Asprova evaluates, documents and displays schedules automatically. These results can be used for direct comparisons, thereby revealing the most optimal planning scenario.

- Amongst the many that Asprova provides:

- Delivery Reliability

- Lead Times

- Inventory Fluctuations

- Resource Productivity

- Waiting Times

- Transportation Times

- Setup Time Proportion

- Custom KPI

- And many more

- The overall quality of the project can be judged according to monetary KPI. Individual orders, resources and items have monetary KPI, as well as a variety of other specific KPI, including:

- Lot Splitting

- Lot Size Reduction

- Capacity Adjustments

- Changes in Manufacturing Processes

- KPIs show in which processes a reduction in setup time is going to have a positive impact on total efficiency.

- Furthermore, it is possible to use KPIs to simulate the undertaking of measures for production efficiency improvement.

Asprova calculates explicit KPIs for continuous improvement of the schedule with every scheduling run. Besides the default KPIs, user-defined KPIs can be added.

Evaluation of Sceneries (Scenarios) (KPIs): You can define evaluation resources to indicate weights to certain elements in order to determine the more optimal schedule based on company key performance indicators (KPIs).

These linked KPIs allow you to evaluate graphically the impact in every single change and element in the overall schedule. With this feature you will be sure that schedule to execute is the most profitable to the company and not just the more convenient for certain area or indicator.