PACKAGING AND PRINTING

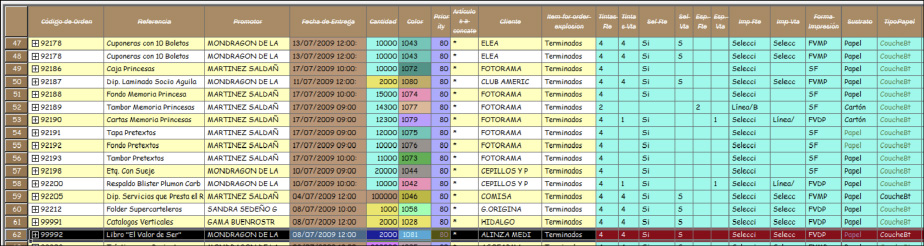

PARAMETRIC BOMS AND GENERIC ITEMS TO CREATE DETAILED ONES BASED ON A MIX OF SPECIFICATIONS (AND) FOR EVERY JOB

ORDER PROMISING, DETERMINE COSTS AND PRICES AND OPTIMAL SEQUENCE WHILE YOU ARE QUOTING EVERY SINGLE SALES ORDER LINE

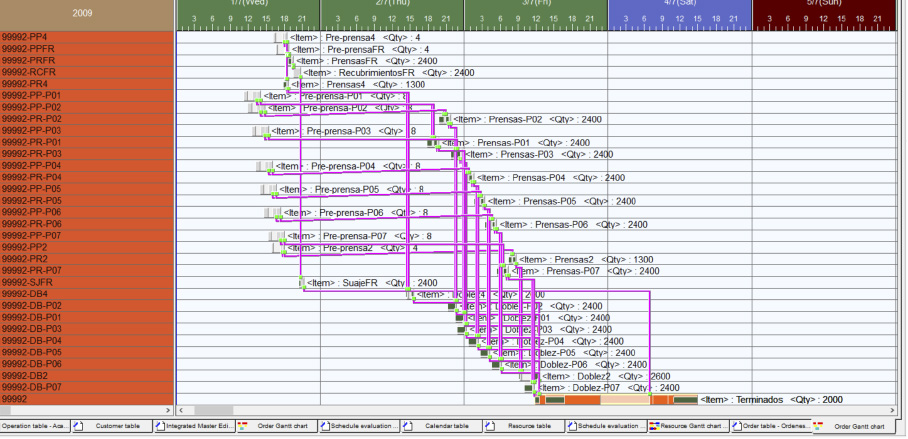

After dynamic introduction of new products, you need to find an optimal assignment of print jobs to each of a set of colour printers, as well as an optimal processing sequence for the set of jobs assigned to each printer. The objective is to minimize the makespan of the schedule to achieve a suitable balance between the workloads of the printers and the efficiencies of the job sequences assigned to the printers.

Typical planning and scheduling challenges that and APS help to fix in packaging and printing industry are:

- Scheduling heuristic that aims to minimise the makespan of a production schedule on parallel machines by scheduling shorter jobs towards the end of the scheduling period by running the rule of The largest-processing-time-first in combinaton with another advanced techniques.

- Capable to promise

- On time delivery rates

- Make ready’s optimization

- Determine in advance the profit for every order / job

- Very short time for new product introduction

- Follow up order compliance based on original order compliance

- Agile method to reschedule delays and un expected events on plant